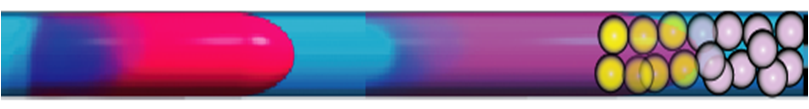

Bead Injection (BI) is the third generation of FIA technique. In its simplest form, a well defined volume of suspension of micro beads is injected into a conduit, where the beads are trapped within a selected location. Next, a sample zone is injected and perfused through the bead layer, while sample components react with functional groups on the bead surfaces. Retained analyte molecules are detected by spectroscopy on solid support in their native form, or reacted with suitable color or fluorescent reagents (Ruzicka 1993,1994). Target molecules may also be eluted for detection downstream. At the end of an assay, beads are transported by flow reversal into a different location or are discarded to waste.

There are two key components that make BI feasible and applicable to real life assays:

Flow programming in Sequential Injection (SI), or in programmable Flow Injection (pFI) format (1.3.14.A.)

Availability of sorbents with suitable mechanical properties and durable functional groups

Flow acceleration makes transport, metering and moving of bead suspension reliable, while slow flow rates enhance capture of analyte on beads packed in a micro column, while flow reversals are used to replace column material, when needed. The programmable Flow injection allows, in contrast to Sequential Injection, processing of larger sample volumes, the essential feature for successful implementation of trace analysis. (1.3.14.A 3.2.2.)

Polymer based spherical beads of suitable dimensions (60 microns or larger) can be moved by microfluidic manipulations and reliably retained in a desired locations. Robustness of functional groups allows repetitive use of beads, a feature which makes BI more practical because column renewal does not have to be frequently performed. However, in cases when frequent and automated renewal of used beads is necessary, reliable methods for keeping beads in well defined suspension by pumping, originally conceived by (Rangel et.al 2012) has been perfected.

As a result, BI technique has been used as a tool for automaton of Sorbent Extraction (SE) and applied for trace analysis in oceanography and environmental studies (Miro 2008, 2014,Horskotte 2016). BI also opens yet unexplored avenues for development of novel (bio)analytical assays, for research in solid-liquid interactions, for study of quality of chromatographic supports, for optimization of immobilization of bioligands on solid supports, and in biology and medical research for study of live cells.

S.M.P. Vidigal , I. V. Tóth, A. O.S.S. Rangel, Talanta 96 (2012) 102–106

J. Ruzicka, C.H. Pollema, K.M.Scudder, Anal. Chem. 65, 3566 (1993)

J. Ruzicka , Analyst 119, 1925 (1994)

M. Miro , S. K. Hartwell, J. Jakmunee, K. Grudpan, E. H. Hansen “Recent developments in automatic solid-phase extraction with renewable surfaces exploiting flow-based approaches’ TrAC 27 (2008) 749

B. Horskotte, P. Chocholous, P. Solich,” Large volume preconcentration and determination of nanomolar concentrations of iron in sea water using a renewable cellulose 8-hygroxyquinoline sorbent microcolumn and universal approach of postcolum eluate utilization in lab-on-valve system. Talanta 150 (2016) 213.

M. Miro “ On chip microsolid –phase extraction in disposable sorbent format using mesofluidic platforms” TrAC 62. (2014) 154.

3. BEAD INJECTION

3.1.1.